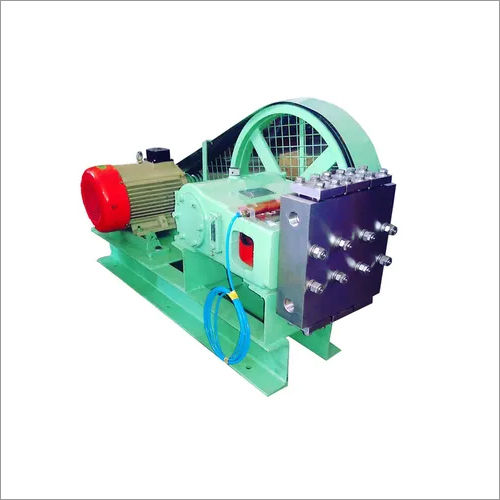

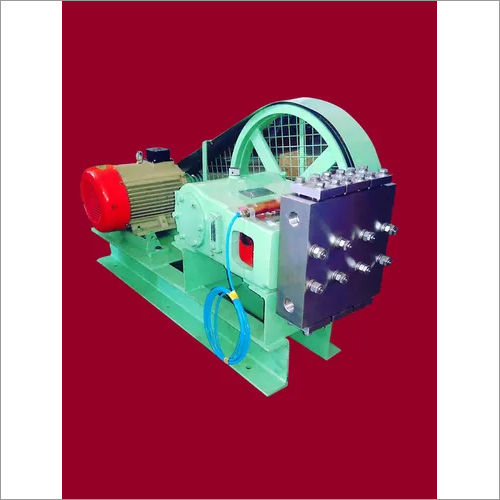

High Pressure Triplex Pump

100000.00 - 500000.00 INR/Unit

Product Details:

- Max Suction Up to 8 meters

- Caliber Accurate plunger diameter, customizable

- Noise Level Low, <85 dB

- Head Size Customizable, available as per required pressure

- Working Temperature Up to 90C

- Inlet/Outlet Flanged connection, SS316

- Fuel Tank Capacity N/A, electric driven

- Click to View more

X

High Pressure Triplex Pump Price And Quantity

- 1 Unit

- 100000.00 - 500000.00 INR/Unit

High Pressure Triplex Pump Product Specifications

- Triplex Plunger Pump

- N/A, electric driven

- Industrial, Hydrostatic Testing, Cleaning, Process, Boiler Feed

- Flanged connection, SS316

- Self-priming

- Electric motor driven

- Up to 90C

- Customizable, available as per required pressure

- Low, <85 dB

- Accurate plunger diameter, customizable

- Up to 8 meters

- 50 Hz / 60 Hz

- 7.5 HP to 30 HP

- Manual/Automatic/PLC controlled

- Custom range, up to 120 LPM

- 400 RPM to 1200 RPM

- High pressure V-packings or plunger seals

- Positive suction

- Triplex High Pressure Plunger Pump

- 25 LPM to 120 LPM

- SS316, Cast Iron, Alloy Steel

- 415V AC, Three Phase

- API 674, ISO 9001:2015

- Reciprocating positive displacement

- High pressure, corrosion-resistant, robust construction, long service life

- High Pressure up to 700 Bar

- Fixed, Base plate mounted

- Max 700 Bar

- Industrial cleaning, hydro testing, water jetting, boiler feed

High Pressure Triplex Pump Trade Information

- 1 Unit Per Day

- 3 Days

Product Description

High Pressure Triplex Pump is widely suited for makingfluid flow under extremely high pressure. It has been designed for optimal toughness and functional reliability. The advantages of the pumps includes high efficiency. It has the ability to make high pressure and makes constant volume irrespective of the type of pressure. Consequently, this pump can fulfill various application demands such as controlled variable flow and others. Offered pump is suited to function with many variable speed drives.

Reliable Performance & Robust Construction

Designed for longevity, the pump integrates a heavy-duty steel base, epoxy paint coating, and stainless steel components, guaranteeing exceptional resilience against corrosion and harsh conditions. The IP55 protection ensures dependable operation even in high-humidity environments, while IE2/IE3 motors contribute to optimal energy efficiency for continuous industrial use.

Tailored Versatility for Varied Applications

Available in a wide range of flow rates and pressures, this triplex plunger pump supports both fixed and mobile setups. Customizable optionssuch as head size, plunger diameter, and mounting typeallow for seamless integration into industrial processes, including hydrostatic testing, boiler feed, and cleaning operations, ensuring maximum adaptability to unique requirements.

Effortless Maintenance & Operator Safety

Thanks to its modular design, the pump allows for quick part replacement and straightforward maintenance. Safety is enhanced with water-cooled packing to minimize wear, low noise emissions under 85 dB, and flexible control systemsincluding manual, automatic, or PLCallowing efficient operation while reducing operator fatigue and risk.

FAQs of High Pressure Triplex Pump:

Q: How does the force lubrication system enhance the pumps reliability?

A: The force lubrication system circulates oil throughout the pump components, minimizing friction and ensuring even cooling of moving parts. This reduces wear and extends the lifespan of critical elements, making the pump highly reliable for continuous industrial operation.Q: What are the primary applications for this high pressure triplex pump?

A: This pump is ideally suited for industrial cleaning, hydrostatic testing, boiler feed, and water jetting operations. Its high-pressure capacity and corrosion resistance make it suitable for various demanding processes across multiple industries.Q: When should the packing be cooled and how does the water-cooled arrangement function?

A: Packing cooling is essential during prolonged or high-pressure operation to prevent seal degradation and maintain pump integrity. The water-cooled packing arrangement circulates water around the packing area, effectively dissipating heat and extending seal life.Q: Where can this pump be installed and what are the mounting options?

A: It can be mounted on a fixed steel base plate or supplied with a mobile trolley for flexible positioning. The rugged design and corrosion-resistant finish make it appropriate for indoor or outdoor industrial environments with up to 95% relative humidity.Q: What is the process for adjusting the flow rate and pressure?

A: Flow rate and pressure can be manually adjusted via the stroke adjustment mechanism. This allows precise calibration of the pump output to meet specific requirements in any given application, providing operational versatility.Q: How does the modular design benefit maintenance and serviceability?

A: The modular design enables straightforward access to individual components, simplifying routine maintenance and part replacement. This reduces downtime and ensures the pump remains operational with minimal interruption, which is critical for industrial workflows.Q: What are the main benefits of using a ceramic or SS316L plunger in this pump?

A: Ceramic and SS316L plungers offer superior wear and corrosion resistance, ensuring a longer service life under high-pressure and challenging fluid conditions. This construction reduces maintenance needs and enhances the pumps performance reliability.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Triplex High Pressure Pumps' category

"All type of liquid and Semi-liquid Homogenizers are available."

|

HARVEST HI-TECH EQUIPMENTS (INDIA) PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese